- 1-800-4-REBUILD

- admin@precisionservicemtr.com

- 121 W. Fullerton Avenue Addison, IL 60101

REBUILD

The term “rebuild” refers to a complete overhaul of a machine to its original mechanical specifications. The mechanical components of the machine are cleaned, inspected, and rebuilt using either new or re-machined parts.

- See More Below!

RESTORING YOUR MACHINE TO LIKE-NEW CONDITION

Precision Service technicians are experts in restoring the condition of your machine to its original operating condition. We understand that your machine is an important aspect of your everyday operations. This pushes us to work in a timely manner to repair or rebuild your machine to get it back in action as soon as possible, saving you time and money.

Getting your machine back to full production is simple! Just call Precision Service MTR where honesty is our policy. We will tell you the truth about what needs to be done and provide you with an honest quote. As a family owned and operated business, we are a Service Partner you can trust!

Featured Rebuild Projects

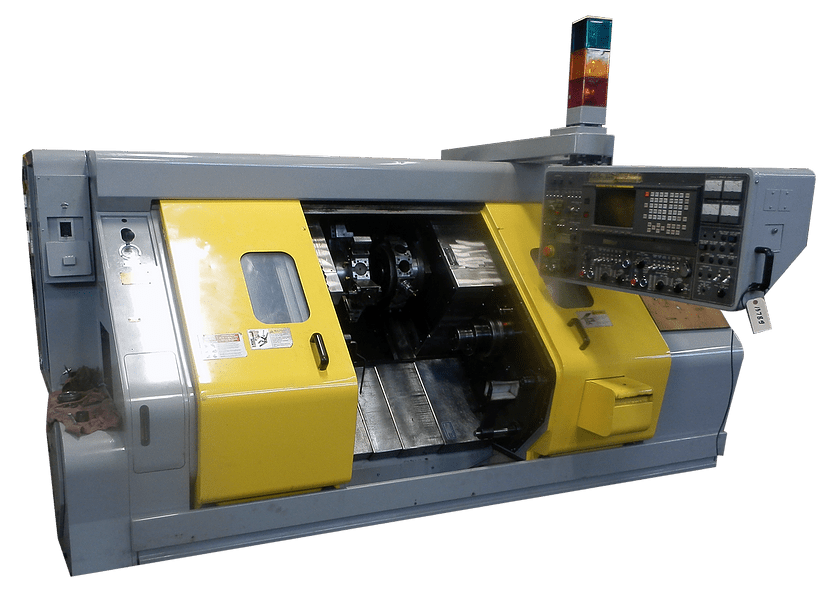

Nakamura Tome TW-10

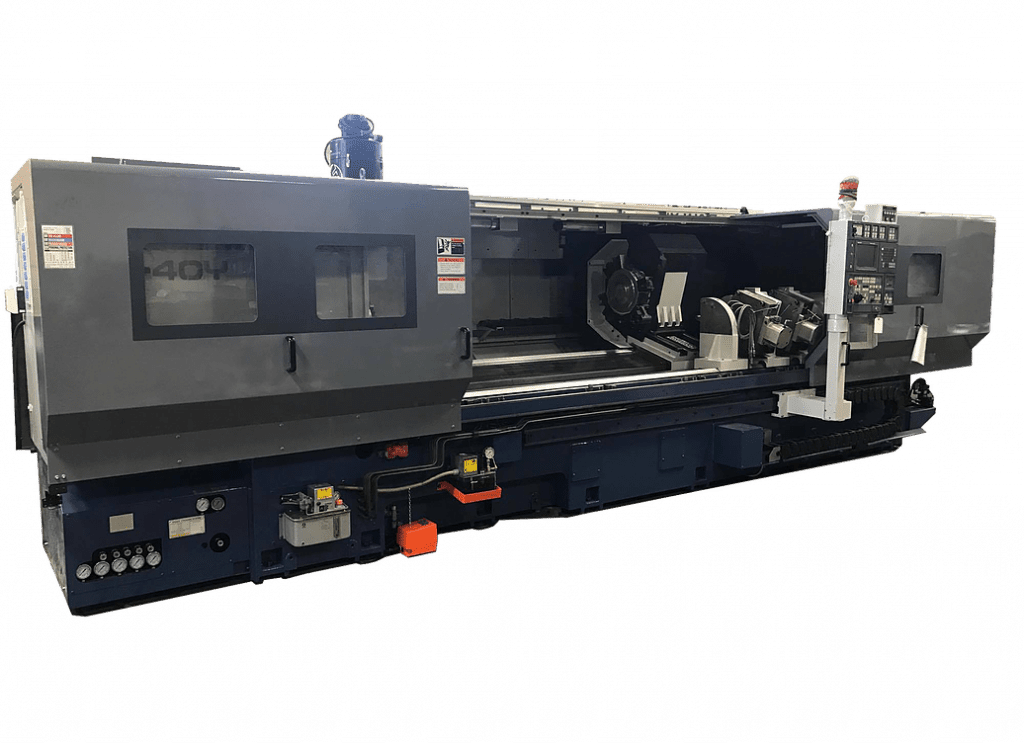

Mori Seiki TL-40Y

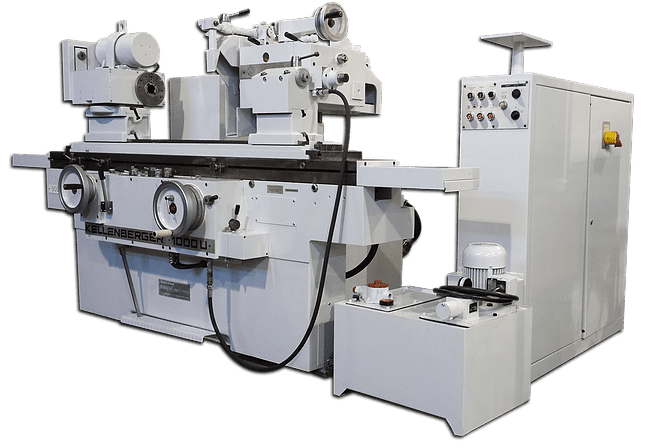

Kellenberger Grinder

Leblond Lathe

Mazak Slant Bed

Oster 716

Landis Threader

Fadal Mill

Mazak Slant Bed

Mazak M5N

"T" Lathe

Mazak Powermaster

Gallmeyer & Livingston Grinder

Mori Seiki ZL-45M

Spindle Rebuild

NAKAMURA TOME TW-10

- Disassemble complete machine

Rebuild main and sub spindle

Install new linear guides

Scrape spots of bed due to rust

Precision aligned linear guides square to each other

Align turrets to spindle, center lines to new ballscrews

Scrape and align new ballscrew brackets on all axis due to rust

- New lubrication system

- Install new spindle drive belts

Rebuild both turrets

Replace hydraulic pump due to leaks

Replace hydraulic and coolant hoses

Replace seal tight

Clean and inspect all drives and boards

Paint and reassemble

MORI SEIKI TL-40Y

Disassemble complete machine

Grind bed ways, upper and lower

Scrape and align headstock base to bed ways

Supply and install turcite to bottom of saddle ways, keeping saddle square to spindle

Way grind top of “X” axis ways

Scrape, flake and master bottom ways of cross slide to saddle

Way grind “Y” axis ways

Precision align “Y” axis to original factory tolerance

Scrape and flake “X”, “Y” and “Z” axis gibs. Upon completion, gibs to have full adjustment

Scrape and master tailstock to bed way keeping parallel to spindle and spindle center line

Align turret to spindle center line

Scrape and align ball screw brackets for flatness (“X”, “Y”, and “Z” axis)

Precision align “X”,”Y”, and “Z” axis ball screws

Replace all lubrication meters and lines as required to assure proper lubrication to all required areas

Install new way wipers

Reassemble and test all machine functions

Kellenberger Grinder

Disassemble and clean machine

Hand scrape and flake all way surfaces true to each other

Rebuild hydraulic pump valves and replace hoses

Rebuild and replace mechanical locks and stops

- Clean electrical system

Replace broken wire and sealtite

New lubrication system

Replace all line and meters

Paint machine to customer code and reassemble

LEBLOND LATHE

Dismantled machine, cleaned, prepped for rebuild

Way ground bed ways to “0” with a clean like new finish

Scraped and aligned saddle to bed using turcite to keep centerline true replacing all metal that was machined and scraped

Scraped and aligned crosslide to top of saddle

Scraped and aligned compound slide

Ground and refit all binders

Scraped and fitted all gibs ensuring full adjustment

New way wipers to keep machine ways debris free

Cleaned and flushed lubrication making sure all lube lines were replaced as needed and new meters installed for proper oil flow to entire machine

New lead screws, thrust bearings, and seals installed on all axis’s

Sanded and painted machine

Reassembled machine back to spec

Powered up and test cut parts giving this Leblond lathe a better than new quality

MAZAK SLANT BED

Dismantled machine tool

Cleaned and visually inspected all units

All components readied for customer’s inspections

Machine, scraped, ground and fit all quoted ways surfaces to full bearing, assuring longer life of all necessary components

Way ground bed ways

Scraped and aligned headstock base to bed, keeping parallel to ways

Way ground “X” axis ways

Scraped and aligned “X” axis slide to “Z” axis bed ways, keeping parallel and square to bed ways

Scraped and flaked all gibs in “Z” axis, leaving maximum adjustment

Scraped ATC slide to “X” axis slide, keeping parallel and square to spindle center line

Scraped and flaked all gibs in “X” axis, leaving maximum adjustment

Scraped, flaked and mastered tail stock to bed way, maintaining spindle center line

Rebuilt “X” and “Z” axis ball screw and nuts

Supplied and installed thrust bearings in “X” and “Z” axis

Realigned “X” and “Z” axis ball screw parallel to axis ways

Cleaned and checked hydraulic system

Replaced damaged or defective hydraulic lines

Surveyed hydraulic pump and motor

Cleaned, inspected, repaired lubrication system in areas of repair, assuring proper oil flow to all required areas

Replaced damaged or defective lube lines and installed new flow units

Supplied and installed new spindle belts

Supplied and installed new way wipers

Replaced seals

Surveyed pocket and pin

Precision aligned to center line of spindle

Megered all axis motor

Assembled and test machine

Set all prox switches, roller switches, roller switches back last comp. tool eye

Checked “droop” and “gain” of all axis

Machine tool was demonstrated for personnel at Precision Service facility

All alignment met or exceeded those of the O.E.M.

OSTER 716

Dismantled Machine tool

Cleaned and visually inspected all units

After cleaning all components and structural castings were carefully inspected for overall condition

Machine, scraped, ground and fit all quoted way surfaces to full bearing, assuring longer life of all necessary components

Ground bed ways, upper and lower

Ground clamping areas of bed

Supplied and installed turcite to bottom of saddle ways

Scraped saddle to bed, keeping saddle square to spindle

Scraped and flaked gibs

Aligned saddle to spindle center line

Cleaned and inspected hydraulic systems

Replaced filters

Replaced all lubrication meters and lines as required to assure proper lubrication to all required areas

Installed new way wipers

Inspected headstock gears

Replaced headstock bearings

Reassembled machine completed and tested all machine functions

LANDIS THREADER

Dismantled Machine tool

Cleaned and visually inspected all units

After cleaning all components and structural castings

were carefully inspected for overall conditionGround bed ways, upper and lower

Ground clamping areas of bed

Supplied and installed turcite to bottom of saddle ways

Scraped saddle to bed, keeping saddle square to spindle

- Scraped and flaked gibs

Aligned saddle to spindle center line

Cleaned and inspected hydraulic systems

Replaced filters

Replaced all lubrication meters and lines as required to assure proper lubrication to all required areas

Installed new way wipers

Reassembled machine completed and tested all machine functions

FADAL MILL

Dismantled machine tool units

Cleaned and inspected all quoted components

All components readied for customers inspection

Machine, scraped, flaked, and fit all quoted way surfaces to full bearing; assuring manufacturer’s specifications and alignments

Removed saddle and table from bed ways

Removed table from saddle

Way ground top of saddle ways, master and gib ways, and binder

Removed old turcite from bottom of table

Supplied and installed new material to bottom of table

Scraped master table and saddle, made table 4 corners 0 to top of table

Supplied and installed material to table gibs and binders

Scraped and fitted table gibs and binders to saddle

Supplied and installed material to bottom of saddle

Scraped master saddle to bed to keep square and parallel to bed ways

Supplied and installed material to saddle gibs and binders

- Supplied and installed material to saddle gibs and binders

Scraped and fitted saddle gibs and binders to bed

Aligned ball screw for table and saddle

The head was removed from column

The ways were cleaned and polished to best as condition

New turcite was installed on head

The head was scraped and precision aligned to column

The binders and gibs were refit

Turcite was installed as required

Gibs were scraped and fit, upon completion, gibs brought to full adjustment

Precision Service sent all ball screws out for inspection

Installed thrust bearings in all axis

Cleaned, inspected, repaired lubrication system in areas of repair; assuring proper oil flow to all required areas

Assembled and test ran machine

Set all proximity switches

MAZAK SLANT BED

- Dismantled machine tool

Cleaned and visually inspected all units

Way ground bed ways

Scraped and aligned headstock base to bed, keeping parallel to master way

Scraped and aligned saddle to bed using turcite to keep machine centerline true

Scraped and flaked all gibs, ensuring max adjustment

Scraped ATC slide to X axis slide, keeping slide parallel and square to spindle center line

Scraped and flaked tail stock to master bed way, maintaining spindle center line

- Installed rebuilt ballscrews, thrust bearings, and seals

Cleaned and flushed hydraulic system

Replaced all corroded and damaged hydraulic lines

Surveyed hydraulic pump and motor

Cleaned and inspected lubrication system for any flaws or damaged areas that need repair, assuring proper oil flow to all required areas

Replaced damaged and defective lube lines, installed all new oil meters

Supplied and installed new spindle belts

Supplied and installed new way wipers

MAZAK M5N

Dismantled Machine tool

After cleaning all components and structural castings were carefully inspected for over-all condition

Machine, scraped, ground and fitted all quoted way surfaces to full bearing, assuring longer life of all necessary components

Surveyed Headstock spindle found no lift check out good

Headstock gears, pinions, input shafts and pulleys were surveyed for excessive wear, cracks and other defects

Found input shaft keys where worn replace with new with new bearings

Ground bed ways and clamping areas

Scraped bottom of headstock base to the bed ways

Supplied and installed turcite to bottom of saddle ways

Hand scraped saddle to bed, keept saddle square to spindle

Way ground top of “X” axis ways removing worn area

Scraped, flake bottom ways of cross slide to saddle

Scraped and flake “X” and “Z” axis gibs to have full adjustment

Tailstock quill was refitted for proper fit to housing

Replaced tailstock seals and bearings

Installed turcite to tailstock base

Scraped tailstock to bed way keeping parallel to spindle and spindle center line

Installed all new seals, packings and bearings in both turrets

Aligned front and rear turret to spindle center line

Sent out “X” and “Z” axis ballscrews to be reconditioned

Installed thrust bearings in “X” and “Z” axis

Scraped and aligned ball screw brackets for flatness (“X” and “Z” axis)

Precision aligned “X” and “Z” axis ball screws

Cleaned hydraulic systems replace filters and all sight glasses

Replaced all lubrication meters and lines as required to assure proper lubrication to all required areas

Installed all new way wipers

Painted machine standard Mazak color code

"T" LATHE

- Dismantled Machine tool

Surveyed headstock spindle and bearings for axial and radial clearance

New bearings where needed due run out and lift

Headstock gears, pinions, and pulleys will be surveyed. No need to be replaced but found input shaft key way where worn replaced with new

Hand scraped and aligned bed square and parallel to spindle

Scraped saddle to bed, keeping saddle square to spindle

Way ground top, leading edge of “X” axis ways

Scraped, flaked and mastered bottom ways of cross slide to saddle

Machine scraped and aligned “Z” axis compound ways

Precision aligned compound square turret to top of compound slide

Scraped and flaked “X” and “Z” axis gibs to have full adjustment

Remanufactured “ X” and “Z” axis ballscrews

Installed new thrust bearings on “X” and “Z” axis ballscrews

Scraped and aligned ball screw brackets for flatness (“X” and “Z” axis)

Precision aligned “X” and “Z” axis ball screws

Cleaned and inspected hydraulic systems

Replaced all hydraulic hoses, filters and sight glasses

Removed and replaced all lubrication meters and lines, retrofit with Lube LHL x 100 grease system and Generation 3 LHLPX1 retrofit panel

Supplied and installed all new way wipers

Installed new spindle drive belts

Painted machine to customers color code

MAZAK POWERMASTER

Dismantled Machine tool

After cleaning all components and structural castings were carefully inspected for over-all condition

Machine, scraped, ground and fit all quoted way surfaces to full bearing, assuring longer life of all necessary components

Surveyed Headstock spindle found no lift check out good

Headstock gears, pinions, input shafts and pulleys were surveyed for excessive wear, cracks and other defects

Found input shaft keys were worn, replaced with new with new bearings

Ground bed ways and clamping areas

Scraped bottom of headstock base to the bed ways

Supplied and installed turcite to bottom of saddle ways

Hand scraped saddle to bed, keeping saddle square to spindle

Way ground top of “X” axis ways removing worn area

Scraped, flake bottom ways of cross slide to saddle

Scraped and flaked “X” and “Z” axis gibs to have full adjustment

Tailstock quill was refitted for proper fit to housing

Replaced tailstock seals and bearings

Installed turcite to tailstock base

Scraped tailstock to bed way keeping parallel to spindle and spindle center line

Installed all new seals, packings and bearings in both turrets

Aligned front and rear turret to spindle center line

Sent out “X” and “Z” axis ballscrews to be reconditioned

Installed thrust bearings in “X” and “Z” axis

Scraped and aligned ball screw brackets for flatness (“X” and “Z” axis)

Precision aligned “X” and “Z” axis ball screws

Cleaned hydraulic systems, replaced filters and all sight glasses

Replaced all lubrication meters and lines as required to assure proper lubrication to all required areas

Installed all new way wipers

Painted machine standard Mazak color code

GALLMEYER & LIVINGSTON GRINDER

Dismantled machine tool

Cleaned and visually inspected all parts

All component readied for customer’s inspection

Machine, scraped, flaked and fitted all quoted way surfaces to full bearing, assuring longer life of all necessary components

Lathe tested spindle for concentricity and alignment

Repaired spindle bearing lands

Supplied and installed spindle bearings our datum point

Scraped and flaked column ways flat and parallel

Scaped, flaked and master spindle assembled to column ways, indicating 4 points “0”

Scraped and flaked bed ways flat and parallel to spindle

- Scraped, flaked and mastered bottom saddle ways to bed ways

Scraped and flaked table flat and parallel to our master granite plate

Scraped, flaked and mastered table ways to top of saddle ways

Repaired Gibs

Scraped, flaked and mastered all gibs and clamps

Cleaned, inspected and repaired lubrication system in areas of repair, assuring proper oil flow to all required areas

Supplied and installed all screws and nuts

Rebuilt table cylinders

Hydraulic system was cleaned and flushed

All hydraulic lines damaged, or fittings were replaced with new

Template is not defined.

SPINDLE REBUILD

Removed wheel head assembly

Removed spindle from wheel head and inspected

Cleaned headstock

Sent spindle out for ceramic coating on bearing surface

Ground spindle

Supplied and installed new spindle bearing, front and rear

Scraped and fit spindle to new spindle bearings

Cleaned and checked spindle lube system

Transported wheel head assembly back to customer

Reassembled wheel head on machine

Adjusted gibs and related parts

Inspected lube to assure proper lube to related parts

Test ran spindle set pressure switches when complete

Common machine tool repair/rebuild operations Precision Service handles include

Replacement of parts

Spindle Repair and Rebuild

Ball Screw Repair and Replacement

Machine/Grind/Scraping

Replacement of Linear Way

Machine, Grind, Hand scrape, and fit all moving machine surfaces

Ensure full bearing and accurate alignment

Apply Turcite, Moglice, or Phenolic

Replace Lubrication for longevity of the ways surfaces

Final testing and inspection

Test run to new machine standards

INTERESTED? REQUEST A QUOTE TODAY ➞